Advanced Reactors

? |

neutron spectrum |

coolant |

temperature |

pressure* |

fuel |

fuel cycle |

size(s) |

uses |

Gas-cooled fast reactors |

fast |

helium |

850 |

high |

U-238 + |

closed, on site |

288 |

electricity & hydrogen |

Lead-cooled fast reactors |

fast |

Pb-Bi |

550-800 |

low |

U-238 + |

closed, regional |

50-150** |

electricity & hydrogen |

Molten salt reactors |

epithermal |

fluoride salts |

700-800 |

low |

UF in salt |

closed |

1000 |

electricity & hydrogen |

Sodium-cooled fast reactors |

fast |

sodium |

550 |

low |

U-238 & MOX |

closed |

150-500 |

electricity |

Supercritical water-cooled reactors |

thermal or fast |

water |

510-550 |

very high |

UO2 |

open (thermal) |

1500 |

electricity |

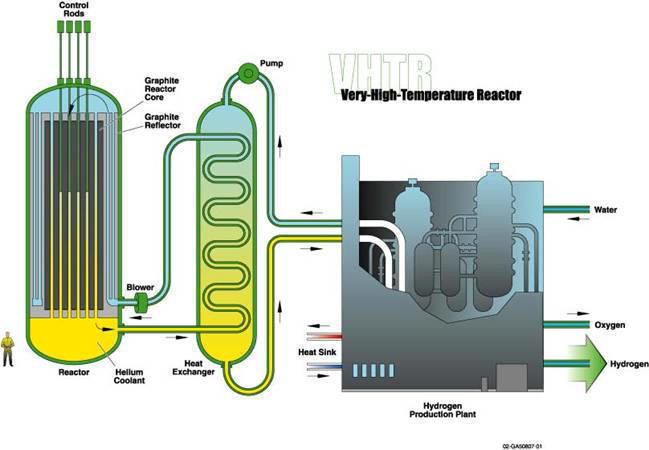

Very high temperature gas reactors |

thermal |

helium |

1000 |

high |

UO2 |

open |

250 |

hydrogen & electricity |

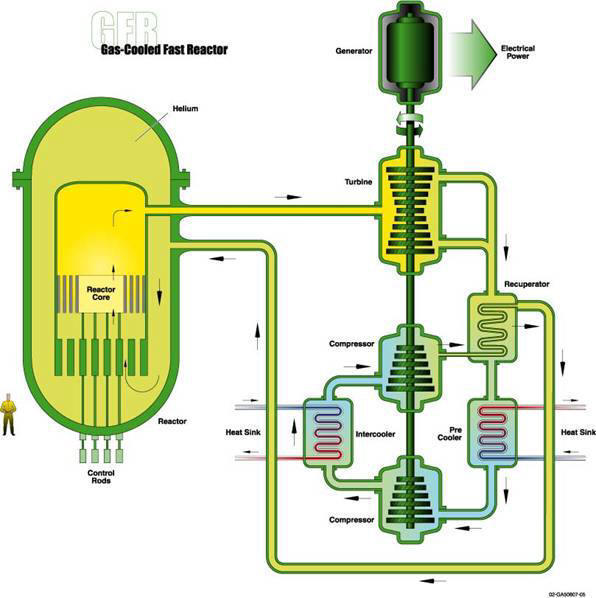

The Gas-Cooled Fast Reactor (GFR) system features a fast-neutron-spectrum, helium-cooled reactor and closed fuel cycle.

Like thermal-spectrum, helium-cooled reactors, the high outlet temperature of the helium coolant makes it possible to deliver electricity, hydrogen, or process heat with high efficiency. The reference reactor is a 288-MWe helium-cooled system operating with an outlet temperature of 850 degrees Celsius using a direct Brayton cycle gas turbine for high thermal efficiency.

Several fuel forms are candidates that hold the potential to operate at very high temperatures and to ensure an excellent retention of fission products: composite ceramic fuel, advanced fuel particles, or ceramic clad elements of actinide compounds. Core configurations may be based on prismatic blocks, pin- or plate-based assemblies. The GFR reference has an integrated, on-site spent fuel treatment and refabrication plant.

The GFR uses a direct-cycle helium turbine for electricity generation, or can optionally use its process heat for thermochemical production of hydrogen. Through the combination of a fast spectrum and full recycle of actinides, the GFR minimizes the production of long-lived radioactive waste. The GFR's fast spectrum also makes it possible to use available fissile and fertile materials (including depleted uranium) considerably more efficiently than thermal spectrum gas reactors with once-through fuel cycles.

****************************************

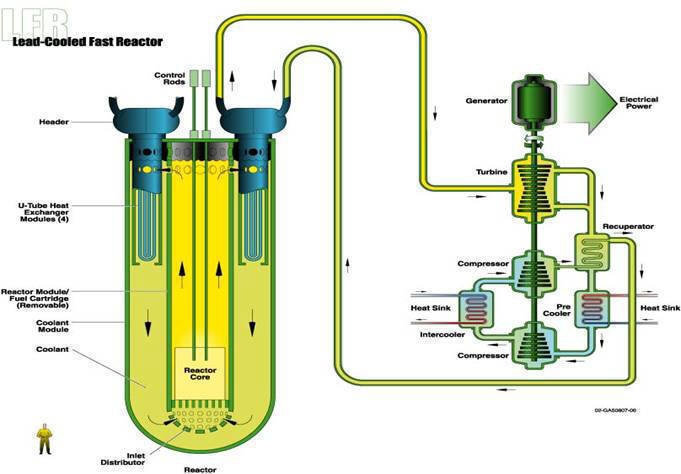

The Lead-Cooled Fast Reactor (LFR) system features a fast-spectrum lead or lead/bismuth eutectic liquid-metal-cooled reactor and a closed fuel cycle for efficient conversion of fertile uranium and management of actinides.

The system has a full actinide recycle fuel cycle with central or regional fuel cycle facilities. Options include a range of plant ratings, including a battery of 50-150 MWe that features a very long refueling interval, a modular system rated at 300-400 MWe, and a large monolithic plant option at 1200 MWe. The term battery refers to the long-life, factory fabricated core, not to any provision for electrochemical energy conversion. The fuel is metal or nitride-based, containing fertile uranium and transuranics. The LFR is cooled by natural convection with a reactor outlet coolant temperature of 550 degrees C, possibly ranging up to 800 degrees C with advanced materials. The higher temperature enables the production of hydrogen by thermochemical processes.

The LFR battery is a small factory-built turnkey plant operating on a closed fuel cycle with very long refueling interval (15 to 20 years) cassette core or replaceable reactor module. Its features are designed to meet market opportunities for electricity production on small grids, and for developing countries that may not wish to deploy an indigenous fuel cycle infrastructure to support their nuclear energy systems. The battery system is designed for distributed generation of electricity and other energy products, including hydrogen and potable water.

This diagram illustrates a schematic concept of the reactor system and does not represent the reference design.

****************************************

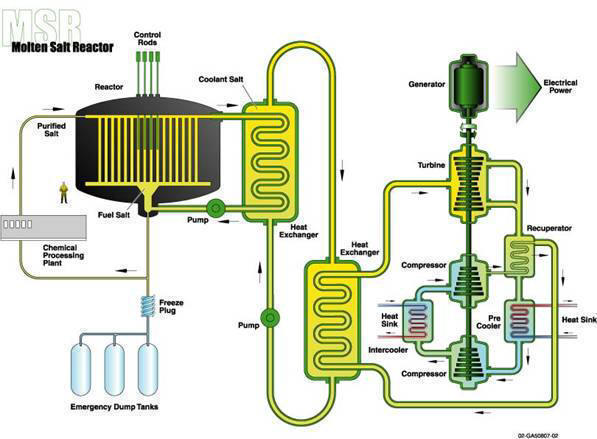

The Molten Salt Reactor (MSR) system produces fission power in a circulating molten salt fuel mixture with an epithermal-spectrum reactor and a full actinide recycle fuel cycle.

In the MSR system, the fuel is a circulating liquid mixture of sodium, zirconium, and uranium fluorides. The molten salt fuel flows through graphite core channels, producing an epithermal spectrum. The heat generated in the molten salt is transferred to a secondary coolant system through an intermediate heat exchanger, and then through a tertiary heat exchanger to the power conversion system. The reference plant has a power level of 1,000 MWe. The system has a coolant outlet temperature of 700 degrees Celsius, possibly ranging up to 800 degrees Celsius, affording improved thermal efficiency.

The closed fuel cycle can be tailored to the efficient burn up of plutonium and minor actinides. The MSR's liquid fuel allows addition of actinides such as plutonium and avoids the need for fuel fabrication. Actinides - and most fission products - form fluorinides in the liquid coolant. Molten fluoride salts have excellent heat transfer characteristics and a very low vapor pressure, which reduce stresses on the vessel and piping.

This diagram illustrates a schematic concept of the reactor system and does not represent the reference design.

****************************************

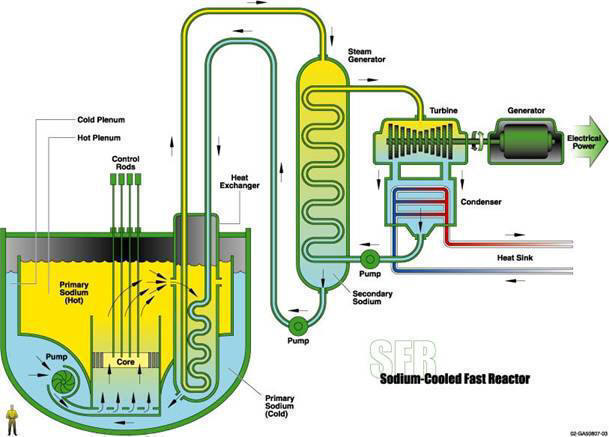

The Sodium-Cooled Fast Reactor (SFR) system features a fast-spectrum, sodium-cooled reactor and a closed fuel cycle for efficient management of actinides and conversion of fertile uranium.

The fuel cycle employs a full actinide recycle with two major options: One is an intermediate size (150 to 600 MWe) sodium-cooled reactor with uranium-plutonium-minor-actinide-zirconium metal alloy fuel, supported by a fuel cycle based on pyrometallurgical processing in facilities integrated with the reactor. The second is a medium to large (500 to 1,500 MWe) sodium-cooled reactor with mixed uranium-plutonium oxide fuel, supported by a fuel cycle based upon advanced aqueous processing at a central location serving a number of reactors. The outlet temperature is approximately 550 degrees Celsius for both.

The SFR is designed for management of high-level wastes and, in particular, management of plutonium and other actinides. Important safety features of the system include a long thermal response time, a large margin to coolant boiling, a primary system that operates near atmospheric pressure, and intermediate sodium system between the radioactive sodium in the primary system and the water and steam in the power plant. With innovations to reduce capital cost, the SFR can serve markets for electricity.

The SFR's fast spectrum also makes it possible to use available fissile and fertile materials (including depleted uranium) considerably more efficiently than thermal spectrum reactors with once-through fuel cycles.

****************************************

This diagram illustrates a schematic concept of the reactor system and does not represent the reference design.

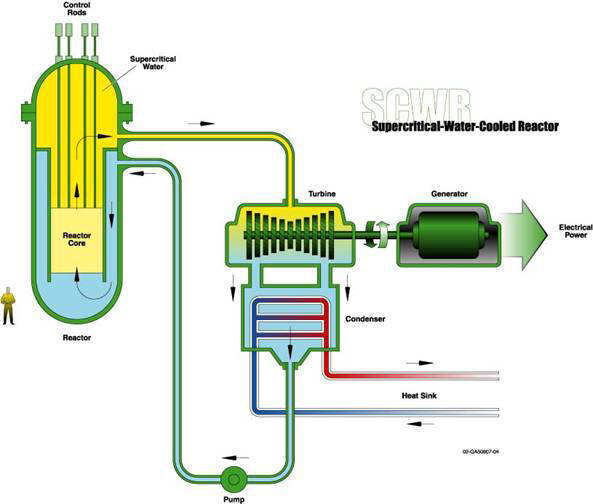

The Supercritical-Water-Cooled Reactor (SCWR) system is a high-temperature, high-pressure water-cooled reactor that operates above the thermodynamic critical point of water (374 degrees Celsius, 22.1 MPa, or 705 degrees Fahrenheit, 3208 psia).

The supercritical water coolant enables a thermal efficiency about one-third higher than current light-water reactors, as well as simplification in the balance of plant. The balance of plant is considerably simplified because the coolant does not change phase in the reactor and is directly coupled to the energy conversion equipment. The reference system is 1,700 MWe with an operating pressure of 25 MPa, and a reactor outlet temperature of 510 degrees Celsius, possibly ranging up to 550 degrees Celsius. The fuel is uranium oxide. Passive safety features are incorporated similar to those of simplified boiling water reactors.

The SCWR system is primarily designed for efficient electricity production, with an option for actinide management based on two options in the core design: the SCWR may have a thermal or fast-spectrum reactor; the second is a closed cycle with a fast-spectrum reactor and full actinide recycle based on advanced aqueous processing at a central location.

****************************************

This diagram illustrates a schematic concept of the reactor system and does not represent the reference design.

The Very-High-Temperature Reactor (VHTR) is a graphite-moderated, helium-cooled reactor with a thermal neutron spectrum.

The VHTR is designed to be a high-efficiency system, which can supply electricity and process heat to a broad spectrum of high-temperature and energy-intensive processes.

The reference reactor is a 600 MWth core connected to an intermediate heat exchanger to deliver process heat. The reactor core can be a prismatic block core or a pebble-bed core according to the fuel particles assembly. Fuel particles are coated with successive material layers, high temperature resistant, then formed either into fuel compacts embedded in graphite block for the prismatic block-type core reactor, or formed into graphite coated pebbles. The reactor supplies heat with core outlet temperatures up to 1,000 degrees Celsius, which enables such applications as hydrogen production or process heat for the petrochemical industry. As a nuclear heat application, hydrogen can be efficiently produced from only heat and water by using thermochemical iodine-sulfur process, or high temperature electrolysis process or with additional natural gas by applying the steam reformer technology.

Thus, the VHTR offers a high-efficiency electricity production and a broad range of process heat applications, while retaining the desirable safety characteristics in normal as well as off-normal events. Solutions to adequate waste management will be developed. The basic technology for the VHTR has been well established in former High Temperature Gas Reactors plants, such as the US Fort Saint Vrain and Peach Bottom prototypes, and the German AVR and THTR prototypes. The technology is being advanced through near or medium term projects lead by several plant vendors and national laboratories, such as: PBMR, GT-HTR300C, ANTARES, NHDD, GT-MHR and NGNP in South Africa, Japan, France, South Korea and the United States. Experimental reactors: HTTR (Japan, 30 MWth) and HTR-10 (China, 10 MWth) support the advanced concept development, and the cogeneration of electricity and nuclear heat application.

This diagram illustrates a schematic concept of the reactor system and does not represent the reference design.

****************************************

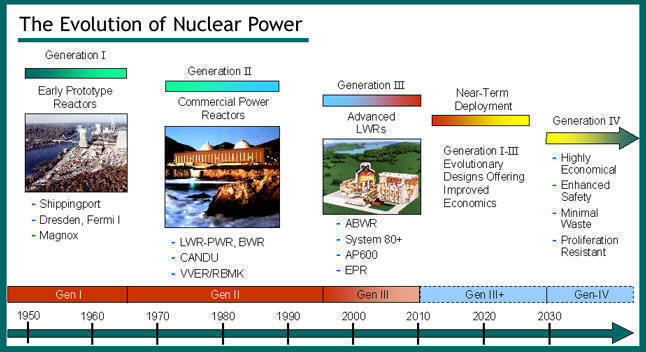

Technology Roadmap for Generation IV Nuclear Energy Systems

The technology roadmap defines and plans the necessary research and development (R&D) to support the next generation of innovative nuclear energy systems known as Generation IV. The roadmap has been an international effort of ten countries, including Argentina, Brazil, Canada, France, Japan, Korea, South Africa, Switzerland, the United Kingdom, and the United States, the International Atomic Energy Agency, and the OECD Nuclear Energy Agency.

Beginning in 2001, over 100 experts from these countries and international organizations began work on defining the goals for new systems, identifying many promising concepts, and evaluating them, and defining the R&D needed for the most promising systems. By the end of 2002, the work resulted in a description of the?six most promising systems?and their associated R&D needs. The six systems feature increased safety, improved economics for electricity production and new products such as hydrogen for transportation applications, reduced nuclear wastes for disposal, and increased proliferation resistance.

?